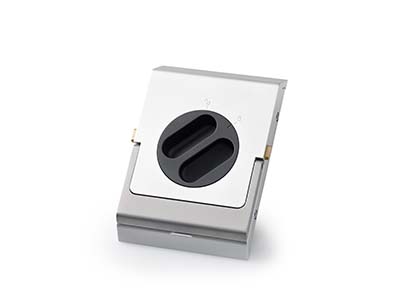

Spotless surface treatment

and flawless CNC machining

/CNC%20milling-3Shape%20(1).jpg)

Characteristics

|

AL-6082 |

Natural anodizing |

|

CNC turning CNC milling |

EN-22768-M |

/CNC%20milling-3Shape%20(1).jpg)

Characteristics

![]() Material

Material

AL-6082

![]() Solution

Solution

CNC turning

CNC milling

![]() Surface

Surface

Natural anodizing

![]() Tolerance

Tolerance

EN-22768-M

Challenge: pleasing demanding clients

With clients in the high-end dental industry, our customer knows what is important: perfect cosmetic appearance and easy useability.

Delivering to this type of client requires an eye for detail and demands that the manufacturing as well as the surface must be spotless. That is why intricate quality control is a necessity when delivering these parts.

Result: perfect surfaces and high-quality manufacturing

The components are made of aluminium alloy AL-6082. Using CNC milling and CNC turning it is possible to manufacture components of high quality and with complex dimensions. Tolerances are according to EN-22768-M standards.

The surface is treated with natural anodising. This type of anodising is transparent so that the underlying material shows through, leaving the surface without a spot.

About the customer

The customer manufactures and delivers dental equipment and software to high-end dentists around the world. Delivering 3D scanners that are easy to use, the products support the dentist in their everyday work.

With a focus on perfection, innovation, and functionality the company is renowned for raising the bar of the industry.

CNC machining – what is it?

CNC machining, or Computer Numerical Control machining, is a manufacturing process that utilises computerised controls and precise machinery. Unlike traditional manual machining methods, CNC machining relies on computer programs to control the movements of cutting tools and other machinery, enabling high levels of precision and efficiency.

The process begins with a digital 3D model of the desired part, which is then translated into a set of instructions using computer-aided design (CAD) software. These instructions guide the CNC machine in performing a series of precise and automated movements.

Other Cases

Your supply chain support

Customised hardware from our extensive network of Asian manufacturers.

We help you establish and maintain a globally competitive supply chain.