CNC machines dedicated to POM

Specialised suppliers of tricky materials

Characteristics

|

POM-C FG |

No scratches |

|

CNC machining |

+/- 0.1 |

/POM-min.jpg)

Characteristics

![]() Material

Material

POM-C FG

![]() Solution

Solution

Machining

![]() Surface

Surface

No scratches

![]() Tolerance

Tolerance

+/- 0.1

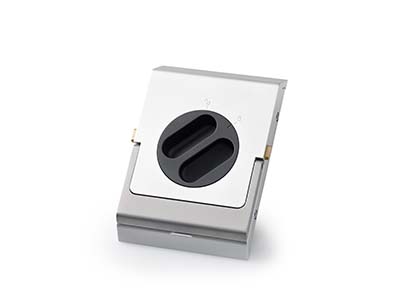

Challenge: Processing plastic to flawless components

When manufacturing these components, two things were essential: Firstly, the machines had to be dedicated to POM. This is important to avoid mixing in other materials from earlier productions.

Secondly, the surface had to be perfect, without any scratches or flaws.

Because of these requirements and the complexity of the material, it was necessary to find suppliers specialised in the field of plastics.

Result: Components for food contact

The material used for the components is POM-C FG. This means that they are suitable for contact with food. They are manufactured using different CNC machining methods, allowing precise dimensions and measurements.

They are manufactured according to tolerances +/- 0,1. Furthermore, the surfaces are carefully controlled throughout.

About the customer

From cutting technology for packaging materials to textiles and composites, this customer thrives on staying ahead.

With offices all over the world, the company delivers cutting solutions around the globe. Offering precise cutting to their clients, this company knows how to provide high standards of quality and credibility in their products and services.

CNC machining – what is it?

CNC machining, or Computer Numerical Control machining, is a manufacturing process that utilises computerised controls and precise machinery. Unlike traditional manual machining methods, CNC machining relies on computer programs to control the movements of cutting tools and other machinery, enabling high levels of precision and efficiency.

The process begins with a digital 3D model of the desired part, which is then translated into a set of instructions using computer-aided design (CAD) software. These instructions guide the CNC machine in performing a series of precise and automated movements.

Other Cases

Your supply chain support

Customised hardware from our extensive network of Asian manufacturers.

We help you establish and maintain a globally competitive supply chain.