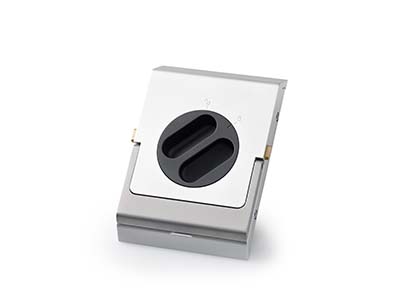

Precision & low tolerances

CNC milling parts strong enough for space

Characteristics

|

Aluminium |

Surtec 650 Powder paint |

|

CNC milling |

K6 Concentricity of 0.03 |

Characteristics

![]() Material

Material

Aluminium

![]() Solution

Solution

CNC milling

![]() Surface

Surface

Surtec 650

Powder paint

![]() Tolerance

Tolerance

K6

Concentricity of 0.03

Challenge: establishing requirements for functionality and quality

Establishing the customer's needs for quality level and functions was the first challenge in this project. In order to offer the best price possible, we had to know exactly what the requirements were.

What the customer needed was a reliable product for their satellites. Moreover, low tolerances were vital to meet the required functionalities of the product.

Given the critical role their satellites play in facilitating global communication, the customer knows that both reliability and quality are non-negotiable. At the same time, price was just as important.

Result: CNC-milling with low tolerances

K6 tolerance standards and concentricity within 0.03 parameters call for a precise production method. CNC milling made it possible to meet these required measurements.

Moreover, the part is made of aluminium, making it lightweight and suitable for the satellite.

The high precision and minimal deviation guarantee stable performance in the harsh conditions of space, while the lightweight construction contributes to the efficiency of the satellite.

About the customer

The customer is a satellite manufacturer, specialising in the design, production, and deployment of high-performance satellites. With a steadfast commitment to reliability, they are a trusted global supplier to both commercial and governmental clients.

Having partnerships with leading industry players and governmental agencies, sets high demands on the satellites. Through continuous product development, the company pushes the boundaries of innovation, creating satellite solutions that cater to the specific needs of global clientele.

CNC milling – what is it?

CNC milling is an advanced manufacturing technique that involves computer-controlled machining and a multi-point cutting tool. This method takes a CAD model as a starting point. A material block is then positioned on a machine bed, and the desired product is cut out.

Other Cases

Your supply chain support

Customised hardware from our extensive network of Asian manufacturers.

We help you establish and maintain a globally competitive supply chain.