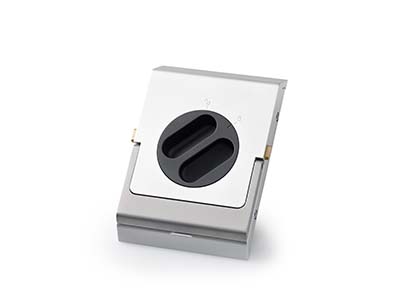

Integrating optics and mechanics

Metal parts for harsh, offshore environments

Characteristics

![]() Material

Material

Stainless steel 17-4PH

Aluminium 6061-T6

![]() Solution

Solution

Mechanical assembly

![]() Surface

Surface

Anti-reflective coating

![]() Tolerance

Tolerance

ISO 2768-1

+0,03/- 0

Characteristics

|

Stainless steel 17-4PH Aluminium 6061-T6 |

Mechanical assembly |

|

Anti-reflective coating |

ISO 2768-1 +0,03/- 0 |

Challenge: parts to outlive saltwater

Saltwater is one of the most challenging environments you can put metal parts into.

Therefore, the requirements for the metal qualities are high when the part is used offshore. These material requirements necessitate suppliers with specialised expertise.

Furthermore, tight tolerances are essential. Assembling lenses and mechanical parts is complex and not possible without precision parts.

Result: an assembly of many part numbers

This module assembly is a conjunction of various precision parts with tolerances as low as +0,03/-0 and adhering to ISO 2768-1. These low tolerances are necessary for the lens of sapphire glass to be mounted.

The metals used for the parts are 17-4PH and aluminium 6061-T6. 17-4PH is a stainless-steel alloy containing chromium, nickel, and copper. This alloy offers high hardness and corrosion resistance, making it useful in the aerospace, petroleum, and firearm industries.

The aluminium alloy (6061-T6) is a precipitation-hardened metal. For major alloying elements, it contains magnesium and silicon. This alloy is often used for heavy-duty structures.

About the customer

This dedicated customer is driven by a commitment to deliver dependable data for well operations.

Their products are used in harsh environments, setting high demands for the quality and technology.

Specialising in down-hole cameras across diverse industries, the company thrives on a foundation of relentless research, thorough testing, and constant development.

Their unwavering pursuit ensures clients access to cutting-edge technology and empowers them with the latest advancements in the field.

Managing assemblies – how we do it

Our assembly process is finely tuned through meticulous supply chain management as well as clean and efficient assembly lines. In supply chain management, we optimise every link, minimising lead times and ensuring a seamless flow of materials and parts. This strategic coordination not only accelerates production but also enhances cost-effectiveness.

Read all about our assembly processes and quality control management here.

Other Cases

Contact Us

Do you have a question or need our help?

Contact us today.