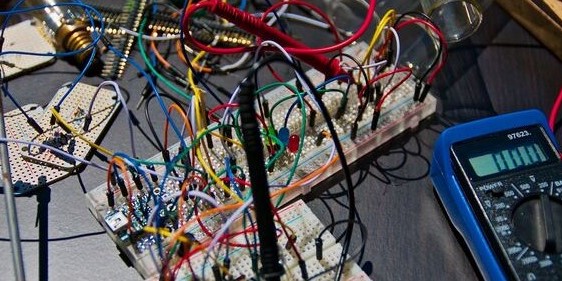

You find electronic devices and box builds everywhere you look. From consumer electronics like your laptop and smartphone to elaborate devices in the industry. In many ways, we rely on the electronics that are produced. This sets high requirements for the manufacturing processes, demanding specialised expertise and resources.

This is where electronic manufacturing services (EMS) play a key role.

What are electronic manufacturing services?.jpg?width=300&height=200&name=thisisengineering-raeng-Q-UJHElsKOc-unsplash%20(2).jpg)

Electronic manufacturing services (EMS) refers to the companies that design, manufacture, test, distribute, and provide return/repair services for electronic components and box build assemblies.

EMS and the more universal term contract manufacturer (CM) are often interchangeably used. They both provide services to original equipment manufacturers (OEM).

EMS offer a wide range of services for the entire life cycle of electronic products. From design, to manufacturing and supply chain, to testing and quality control.

What do electronic manufacturing services offer?

|

Design and engineering support EMS companies often provide design and engineering support. They help their customers in creating and refining product designs, enhancing performance, and ensuring manufacturability and cost-effectiveness. This is a value-adding service that results in a better product.

|

|

Prototyping and new product introduction (NPI) EMS providers can create prototypes for new products, enabling their customers to test and refine their designs before full-scale production. After the testing, the EMS have expertise in managing the transition from prototype to mass production. This scaleability is not only helpful at the beginning of the product journey but also in times of higher consumer demand.

|

|

Supply chain management Efficient supply chain management is a crucial aspect of EMS. You can get help in sourcing the necessary components, managing inventory, and ensuring timely delivery of materials, reducing the risk of production delays. Especially in box build assemblies, this is vital because of the many different components and suppliers involved.

|

|

PCBA and PCB manufacturing EMS providers specialise in PCBA, including surface-mount technology (SMT) and through-hole technology (THT). Read all about PCBA and its importance to box build here.

|

|

Testing and quality control To ensure well-functioning devices testing and quality control is unavoidable. These procedures are an integral part of EMS. The services ensure that the manufactured products meet the needed quality standards and comply with all industry-specific regulations and certifications.

|

|

Box build and system integration EMS companies often offer box build services, which involve the complete assembly of the final product. This includes the integration of electronic components into the final enclosure or casing. Learn about the aspects of box build here.

|

|

Logistics and distribution EMS providers manage logistics and distribution. This ensures that the finished products are shipped and delivered efficiently to their destinations, both nationally and internationally.

|

|

After-sales support and repair services Many EMS providers offer after-sales support and repair services, ensuring that products continue to function optimally and meet the expectations of the end-users.

|

The benefits of electronic manufacturing services

Developing and manufacturing box builds and electronic devices is complicated. It demands a high level of knowledge and a big network of suppliers. Partnering with EMS providers eases some of this. They can offer:

- access to specialized expertise and resources without the need for significant investments in infrastructure and machinery.

- streamlined production processes leading to cost savings and improved time-to-market.

- flexibility and scalability, enabling companies to adapt to market demands and production fluctuations.

- quality assurance and compliance with industry standards and regulations.

What is the difference between CM and EMS?

Electronic manufacturing services (EMS) and contract manufacturing (CM) are two closely related company types. There are slight differences between the two though.

Both EMS and CM offer an overlapping range of services, only the focus may vary.

Often EMSs are more involved in the developing process than the contract manufacturers. This means that their respective clientele generally differs from each other. Where contract manufacturers sell to bigger customers with ready-to-make drawings, EMSs are more involved with smaller companies who need support in product development.

Overall, you can say that CM is focused on the manufacturing of a product and EMS is more involved in product development. These variations are general though and vary depending on the specific company.

What is the difference between OEM and EMS?

An OEM, or Original Equipment Manufacturer, is a company that designs and manufactures products own specifications and brand.

OEMs are responsible for the entire process of product creation, from the initial design and engineering to the manufacturing and branding of the final product. They either choose to manufacture their products in-house, or they outsource to a third-party manufacturer – EMS or CM.

The main difference is thereby that electronic manufacturing services (EMS) provide products/parts for the original equipment manufacturers (OEM).

The future of EMS

As the demand for innovative electronic products continues to grow, the role of EMS providers will become even more critical.

EMS providers play a key role in box build and electronic assemblies, as they provide many companies with their services.

Are you looking for a manufacturer for your assembly? Learn how we can help you with every aspect of your product assembly here.