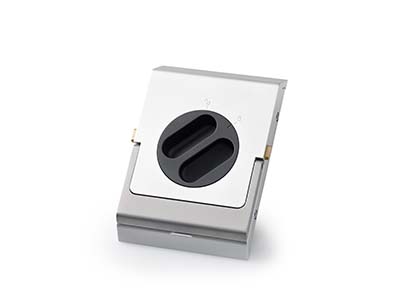

Integrating lenses, mechanics, & electronics

Optical assembly & innovative quality testing

/Mechanical%20assembly-Cellavision%20(1).jpg)

Characteristics

|

Mechanical parts Cables Optics/lenses |

Soldering ESD-safe electronic assembly Electromechanical assembly Optic integrations in clean room

|

|

BOM management Material Requirement Planning Warehousing and quality control Supplier control |

+/- 0.1

|

/Mechanical%20assembly-Cellavision%20(1).jpg)

Characteristics

![]() Material

Material

Mechanical parts

PCBA

Cables

Optics/lenses

![]() Manufacturing

Manufacturing

Soldering

ESD-safe electronic assembly

Electromechanical assembly

Optic integrations in clean room

![]() Solution

Solution

BOM management

Material Requirement Planning

Warehousing and quality control

Supplier control

![]() Tolerance

Tolerance

+/- 0.1

Challenge: handling optical assembly

This project presented several challenges. Firstly, finding a supplier of lenses is a task that requires some expertise. Lens manufacturing is a challenging and specialised field, making it important for buyers to pay extra attention.

For the optical device to function properly it is important to keep the lens clean throughout the entire assembly. Therefore, the integration of the lens happened in a low-dust room.

In the assembling of the lens, we had to test different methods of glueing. This was in order to guarantee that the lens stays fixed. Furthermore, we developed a new method of testing if the lens was glued on properly and would remain so.

Result: detailed work instructions

After adjusting the assembling and the testing methods, the customer acquired two things: intricate work instructions about the module assembly and the optical product itself.

The work instructions are our way of ensuring that all assembly operators know exactly how the processes run. This detailed documentation safeguards the quality of the product as well as the efficiency of the manufacturing.

About the customer

This customer is a company with a vision: to digitise manual blood analysis. To do this, precision and high quality are essential factors.

Committed to innovating the industry, the customer provides technologies that enable accurate and efficient analysis processes.

The company is located in Sweden and has over time developed into an international market leader. With both clients and employees all over the world, they are a trusted player in the market.

Managing assemblies – how we do it

Our electronic assembly process is finely tuned through meticulous supply chain management as well as clean and efficient assembly lines.

In supply chain management, we optimise every link, minimising lead times and ensuring a seamless flow of materials and parts. This strategic coordination not only accelerates production but also enhances cost-effectiveness.

Read all about our assembly processes and quality control management here.

Other Cases

/Electronic%20assembly-Welltec%20(1).jpg?width=2000&height=2000&name=Electronic%20assembly-Welltec%20(1).jpg)

Integrated assembly

/Mechanical%20assembly-Phase%20One%20(1).jpg?width=2000&height=2000&name=Mechanical%20assembly-Phase%20One%20(1).jpg)

/EAconnect%20dec20.jpg?width=573&height=573&name=EAconnect%20dec20.jpg)

Your supply chain support

Customised hardware from our extensive network of Asian manufacturers.

We help you establish and maintain a globally competitive supply chain.