A box build can be everything from the earpiece of your headphones to an industrial device.

The assembly process is complex with a lot of possible pitfalls because of the many different components, suppliers, and sub-assemblies. That is why finding the right suppliers with the relevant expertise is essential for a successful box build assembly.

In this case study, we dive into the details of the ChocoMeter, a box build we assembled for Aasted. In the end, you will know about 4 different factors that make managing a box build assembly easier.

Chocolate quality test

Some time ago the well-established chocolate manufacturer approached us with a challenge. One of their devices had numerous problems at the time. They needed support in the development of an updated version.

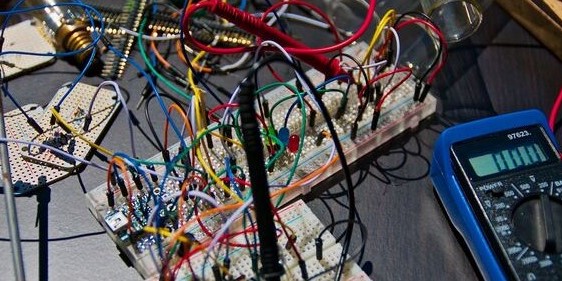

The device allows the customer to measure a small sample of the chocolate mass to check and monitor the viscosity of the tempered chocolate.

Consisting of 35-40 components from different suppliers the box build assembly was complicated. This required exceptional supply chain management. Having that many components delivered at the right time in the right quality takes meticulous planning.

Another hurdle is that suppliers often require a large order, leaving a large amount of unused components in stock. There are various ways of dealing with this issue, but it is a lot of work.

Top tips on managing box build assembly

Many companies outsource their box build processes to electronic manufacturing services or contract manufacturers because it is a complex process. Thinking about the following can make the quality higher though.

Specialised suppliers

Finding a highly specialised manufacturer for each component is an important step towards high quality. If just one component fails to meet the standards, the credibility of the entire assembly can be at risk. A specialised supplier can help you with the appropriate materials, production methods etc. resulting in the best possible component.

Industrial hubs

Finding an industrial hub for your assembly will gather the processes, making the quality loop shorter. If one component is faulty, the responsible manufacturer is located close by for correcting. Read more about navigating industrial hubs.

Work instructions

Make sure to map out every step in the assembly process. By making detailed work instructions for your project, every person on the way knows what to do to manufacture a perfect box build.

Supply chain management systems

Managing a large number of components and suppliers requires a system that can handle all relevant information. You will find many different software suppliers offering different services. Do your research and find the system best suited to your needs.

Avoid ending up in chaos

The complexity of a box build assembly is enormous. As a result, many projects end up in chaos and an endless series of problems.

Like a recipe, you need a detailed list of ingredients and accurate work instructions so that no step in the process goes wrong. You need the right suppliers, and if these are near to each other, even better.