The need for manufacturing solutions keeps growing in the rapidly evolving global market that we have today.

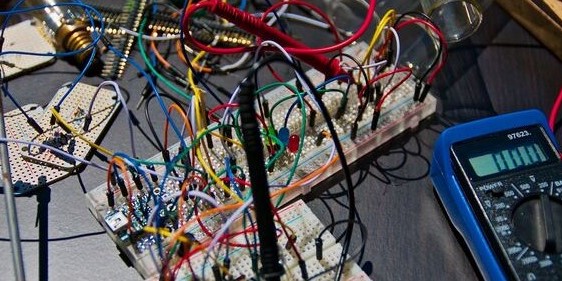

And so does the role of contract manufacturers. Ensuring a streamlined development and delivery of complex products, they contribute to the overall success and competitiveness of businesses. In the realm of box build assembly, contract manufacturers hold a key position. They are often responsible for the assembly of a fully functional product, including both the electronic and mechanical components.

This sophisticated process requires attention to detail, technological expertise, and an understanding of the intricate interplay between hardware and software integration.

Want to learn about the different aspects of box build? Read this article about everything from the components to outsourcing of box build assembly.

In this article, you will learn about the aspects of contract manufacturing, as well as the advantages and risks of collaborating with a third party.

What is contract manufacturing?

Contract manufacturing refers to the outsourcing of certain production activities or the entire manufacturing process..png?width=600&height=600&name=Supply%20chain%20management%20(1).png)

This means that a company hires the contract manufacturer to produce certain components or complete products on their behalf.

The client company typically provides the specifications, technology, and intellectual property (though sometimes the CM will support this as well).

The contract manufacturer is then responsible for the actual production process, including sourcing raw materials, supply chain management, manufacturing, quality control, and the distribution of the finished goods.

This practice allows companies to leverage the expertise, specialized capabilities, and infrastructure of contract manufacturers without having to invest in their own production facilities.

It is commonly used in various industries, including electronics, pharmaceuticals, automotive, and consumer goods, among others.

Contract manufacturing supports you in the production process, letting you focus on your core competencies.

Benefits of contract manufacturing

There are multiple reasons why you should consider using a contract manufacturer for your box build project.

Tapping into experience and supplier network

Contract manufacturers are focused on their expertise. This means that you will benefit from both specialised experience and a network of suppliers, saving you the time of learning a new industry and its aspects of succes.

Reduced costs

Because the contract manufacturer is already settled into the industry, you do not have to put money into new production machines, employees and so on. This will save you not only time, but it will also reduce the costs of introducing a new product.

Faster time to market

Your contract manufacturer is already set to go. This means that your product is ready to be manufactured as soon as you have the drawings ready.

Flexible capacity

Not only is the time to market fast but you will also profit from high scaleability. Because of the contract manufacturers’ supplier network, you can adjust your production to the market demands.

Developing products

Depending on your contract manufacturer some will offer to help you develop your products. This can be in terms of quality, functionality, and what other needs you and your customers might have.

Risk of contract manufacturing

Nothing is risk-free – the same holds for collaborating with contract manufacturers.

Giving up control

When you hire a contract manufacturer to make your product, you give up some of the control in the production. This is why it is important to build a close relationship and make sure that your company values align with the manufacturer’s.

Risk of outsourcing to other countries

Outsourcing your production comes with many benefits. But it also comes with some risks regarding cultural differences and language barriers. Make sure that your contract manufacturer has the experience and skill set to handle business in the respective countries.

Quality concerns

Outsourcing production means outsourcing quality control. Be sure to ask how your contract manufacturer handles quality control and testing throughout the manufacturing process.

What is the difference between CM and EMS?

Contract manufacturing (CM) and electronic manufacturing services (EMS) are often used interchangeably. There are slight differences between the two though.

Both company types offer an overlapping range of services, only the focus may vary.

Often EMSs are more involved in the developing process than the contract manufacturers. This means that their respective clientele generally differs from each other. Where contract manufacturers sell to bigger customers with ready-to-make drawings, EMSs are more involved with smaller companies who need support in product development.

Overall, you can say that CM is focused on the manufacturing of a product and EMS is more involved in product development. These variations are general though and vary depending on the specific company.

Finding the right contract manufacturer

It is important to thoroughly research your supplier before signing any contract. Be sure to know your own needs and compare them to the contract manufacturers’ services.

Want to know how we can help you along? Read all about our assembly services here.