Electronics are key for many products. All the more important is it to ensure that the electronic devices are manufactured to the highest quality standards possible.

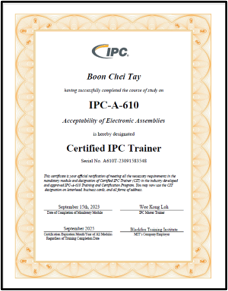

The IPC-A-610 certification, developed by the Association Connecting Electronics Industries (IPC), plays a crucial role in reaching and maintaining these standards. This certification is widely recognised in the industry, providing guidelines for the acceptability of electronic assemblies.

In this blog post, we will delve into the IPC-A-610 certification, focusing on its requirements for box build assemblies, PCBAs (Printed Circuit Board Assemblies), and cables.

IPC-A-610 certification – a broad set of standards

The IPC-A-610, also known as the Acceptability of Electronic Assemblies, is a comprehensive document that sets the standard for electronic assembly acceptance criteria. For electronic manufacturing services and companies alike, it is an important certificate.

This certification covers various aspects, including materials, components, and assembly processes. The standards aim to ensure reliability and consistency in electronic assemblies.

It is used by electronic manufacturers to establish the quality requirements needed for the intended use. But also as a common reference point for customers, suppliers, and regulatory agencies.

The 3 levels of requirements

There are three classes in the IPC-A-610 standards, referred to as class 1, class 2, and class 3. Manufacturers and assemblers use the class definitions to guide their processes and ensure that the appropriate level of quality is maintained based on the intended application of the electronic assembly.

Understanding these classes helps establish clear expectations for both manufacturers and customers in terms of quality and reliability.

IPC-A-610 class 1 - General electronic products

This class is suitable for electronic assemblies where the primary focus is on functionality rather than high-reliability performance. It may be used in applications where the consequences of product failure are minimal

Class 1 has the most relaxed criteria, allowing for cosmetic imperfections and minor deviations from the ideal standards. This class is generally applicable to consumer electronics and products with a short expected lifespan.

IPC-A-610 class 2 - Dedicated service electronic products

Class 2 is intended for electronic assemblies that demand higher reliability and extended performance but don't fall into the category of critical or high-performance applications.

It is applicable for products that are expected to function correctly over an extended period without frequent maintenance or repair.

This class is often applicable to industrial electronics, where reliability is important but not critical.

IPC-A-610 class 3 - High-performance electronic products

Class 3 is reserved for high-performance electronic assemblies used in critical applications where the highest level of reliability and performance is essential.

Products in this class are expected to function often in harsh environments or other critical settings.

The emphasis is on achieving the highest level of reliability and performance. This class is reserved for products where failure could have serious consequences, like aerospace, medical devices, or military equipment.

Requirements for box build assemblies

Box build assemblies involve the integration of electronic and mechanical components into an enclosure or "box."

The quality control stage of the manufacturing process is vital for the product. Because of the complexity of these assemblies, many things can go wrong throughout.

IPC-A-610 provides specific requirements for box build assemblies. These requirements encompass factors such as component placement, mechanical assembly, and soldering, among others.

Key requirements for box build assemblies according to IPC-A-610 may include:

- Proper alignment and orientation of components within the enclosure.

- Adequate mechanical support and attachment of components.

- Proper strain relief for cables and wiring.

- Correct assembly of connectors and interfaces.

- Compliance with specified cleanliness standards.

Requirements for PCBAs (Printed Circuit Board Assemblies)

PCBAs are essential for a well-functioning electronic device. Therefore, adherence to strict quality standards is crucial for product reliability.

IPC-A-610 outlines specific criteria for evaluating the acceptability of PCBAs. These criteria cover a wide range of aspects, including soldering quality, component placement, and overall workmanship.

IPC-A-610 requirements for PCBAs may include:

- Acceptable solder joint criteria, including fillet size and shape.

- Proper component orientation and placement on the PCB.

- Adequate spacing between components to prevent electrical interference.

- Correct polarity of polarized components.

- Compliance with specified cleanliness and contamination standards.

Requirements for cables

Cables play a vital role in electronic assemblies, as they provide connectivity and transmit signals.

IPC-A-610 extends its guidelines to include cable assemblies, ensuring that they meet the necessary quality benchmarks.

Key requirements for cables according to IPC-A-610 may include:

- Proper termination and crimping of connectors.

- Adequate strain relief for cables.

- Correct routing and bundling of cables.

- Compliance with specified electrical and mechanical characteristics.

- Inspection for any visible defects or damage to the cable.

Reliable and save electronic devices

The IPC-A-610 certification serves as a valuable tool for manufacturers, suppliers, and customers. It ensures that electronic assemblies, including box build assemblies, PCBAs, and cables, meet the highest quality standards.

By incorporating and maintaining IPC-A-610 compliance, companies enhance the reliability, performance, and overall quality of their electronic products.