Laser cutting of cables is a manufacturing technique that precisely and efficiently severs cables of various materials and sizes. This advanced technology allows a highly accurate and rapid method for achieving clean, uniform cuts, convenient for various purposes.

See how it is done in this video.

Cutting cables with a laser offers several advantages over manual cutting methods. Here are some key benefits:

Precision and accuracy

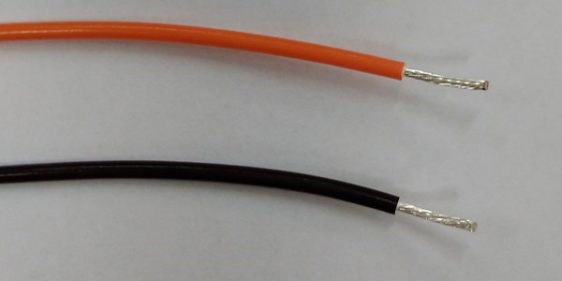

Laser cutting can create clean, straight cuts with minimal deviation from the desired dimensions. This ensures a consistent and precise cut to the required length. The method allows a clean cut of the insulation without damaging the core.

Speed and efficiency

Lasers can cut through multiple cables simultaneously, reducing manufacturing time and costs significantly, compared to manual cutting, which is both time-consuming and labour-intensive.

Less material waste

Laser cutting optimises the use of cable lengths, reducing scrap and saving on material costs, whereas manual cutting often results in uneven and wasteful cuts.

Clean and Sealed Ends

Leaving the cable ends clean and sealed, laser cutting prevents fraying and ensures that the cables are ready for immediate use without the need for additional finishing or treatment.

Cables are everywhere

Cables play a pivotal role in most technical devices. For example, a box build assembly relies on cables to function. They ensure the efficiency, reliability, and safety of most devices and many industrial processes.

Because of their essential role in manufacturing a fully functional device, quality is most important. A cable quality standard is the IPC-A-610, defined by the Association Connecting Electronics Industries (IPS). This standard is divided into 3 classes, each with different levels of requirements, making it suitable for various types of cables and cable needs.